Environmental Monitoring

Objectives

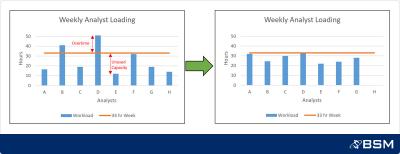

Our client, a leading pharmaceutical company, engaged us to help reduce their substantial overtime spending.

Solutions Deployed

-

Redesign of process flows to remove redundancies

-

EM and Water sampling plans designed to limit travel time and level number of samples collected daily

-

Queue-based leveling employed to reduce testing volatility

-

Cross-training plan implemented to reduce analyst test dedication

-

Created balanced, productive daily roles for analysts

-

Implemented a consumable inventory management system to control ordering and reduce the frequency of media receipt

Results

-

Daily EM and Water sample collection volatility reduced by 83%

-

EM and Water sampling time reduced by 30-57%, respectively

-

Membrane filtration and spread pour plate reads reduced by 43%

-

Endotoxin testing runs reduced by 60%

-

Material ordering/receipt reduced by 45%

-

Growth promotion testing reduced by 53%

-

Cross training increase of 30%

-

Productivity increase of 50%

-

Released 1 FTE from sampling/testing to focus on studies/projects

-

Overtime reduced by 90%

-

Direct savings of >$200,000 per year